ADVANTAGES OF HAVING PARTS CUT BY WATERJET:

- Elimination of tool cost for small volume and prototype work

- Minimal kerf width of 0.030″

- No heat thermal distortion or degradation of materials

- No noxious gases

- Part accuracy of ±0.005″

- Can cut up to just under 7″

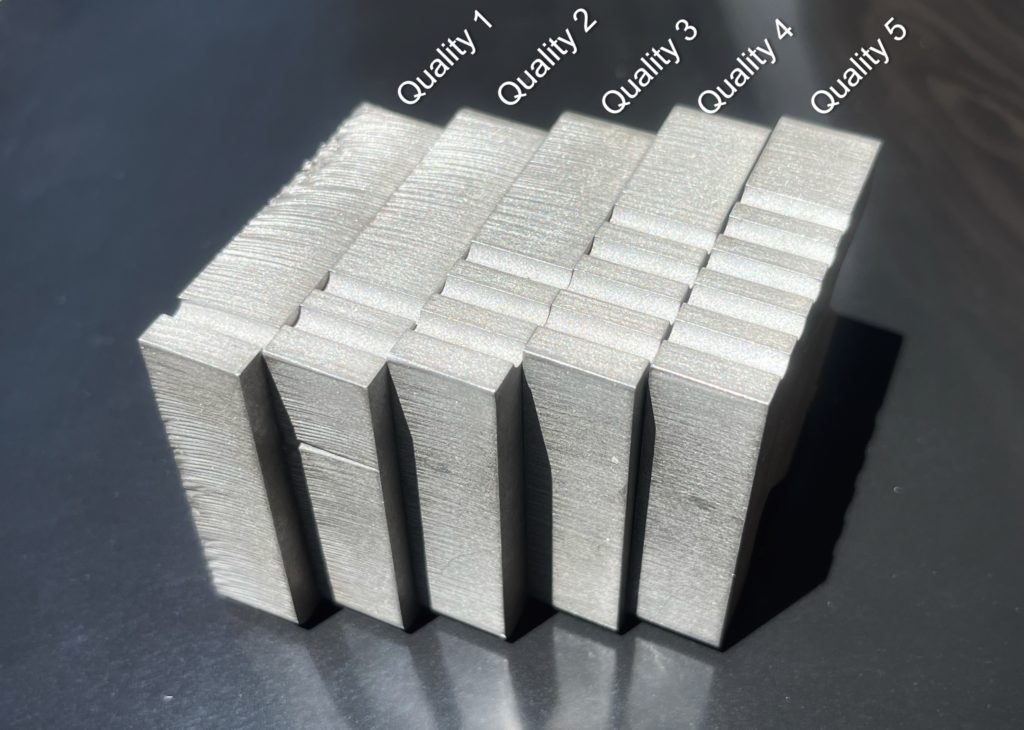

The waterjets cut at five different quality levels. A material will be cut the fastest at quality one, while best edge quality at quality five. Here is a visual example of material cut at different settings:

DISADVANTAGES OF HAVING PARTS CUT BY WATERJET:

- Materials we avoid: tempered glass, ceramic, mdf (medium-density fibreboard), magnesium